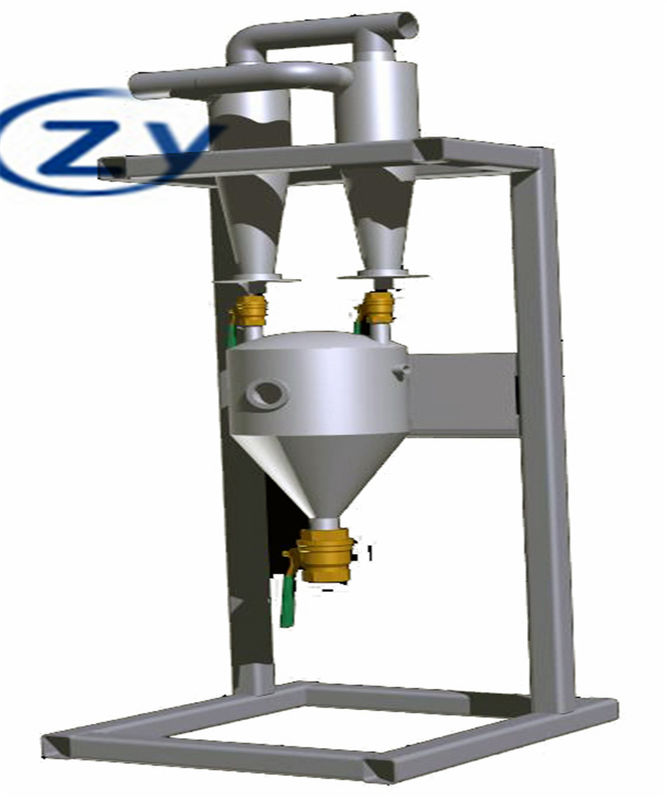

Gıda kalitesi paslanmaz çelikli manioka nişastası Desander -Manioka nişastası işleme makinesi olarak satın alınmak üzere

Ürün ayrıntıları:

| Menşe yeri: | Çin |

| Marka adı: | ZY |

| Model numarası: | DS |

Ödeme & teslimat koşulları:

| Min sipariş miktarı: | 1 takım |

|---|---|

| Fiyat: | 2000-999999USD |

| Teslim süresi: | İmza satışından 15 gün sonra iletişim kurun |

| Ödeme koşulları: | L/C,T/T |

| Yetenek temini: | ayda 20 takım |

|

Detay Bilgi |

|||

| Garanti: | 1 Yıl | Boyut: | Standart Boyut |

|---|---|---|---|

| Malzeme: | SS304 | Başvuru: | nişasta üretimi |

| Ambalaj: | standart ambalaj | Tip: | DS2 |

| Renk: | Gümüş beyaz | nihai ürünler: | Süper İnce manyok nişastası |

| Malzeme Kapsamı: | manyok, patates, tatlı patates | Avantaj: | Yüksek Verimli |

| Vurgulamak: | paslanmaz çelik manioka nişastası desander,Gıda sınıfı mansoç nişastası makineleri,Nişasta işleme desander garantisiyle |

||

Ürün Açıklaması

Gıda kalitesi paslanmaz çelikli manioka nişastası Desander -Manioka nişastası işleme makinesi olarak satın alınmak üzere

1.Çalışma prensibi:

Merkezi çekme bölme teknolojisiyle çalıştırılan,Eksantrik silindirli su girişinde, siklon kum girişinden su girerken önce aşağıya doğru hareket eden çevresel olarak aşağıya doğru hareket eden aşağıya doğru bir dokunuş sarmalı oluşturur.Bir kez belirli bir konüs bölümüne çarptığında, akım yukarı aksyal dönüşe ters döner ve çıkış borusundan çıkar. Kirlilikler, inersiyel merkezkaç kuvveti ve yerçekimi ile çekilir.Alt konik çamur kovasına yerleşmek (yükselenme karşıt bileşenler yeniden çekilmeyi durdurur)Kirlilikler oluştuğunda, kolayca su ile akıtılan boşaltma için el valfini açın.

2Desander'ın açıklaması:

Desand hidrat siklonu, esas olarak ezilmiş nişastalı gübre, maniak gübre ve patates gübreinden kum ve çamur çıkarmak için kullanılır.Buğday nişastası, sago ve patates nişastası işleme.

3.Özellikleri ve faydaları:

- Tüm ürünler yüksek dayanıklılık ve uzun dayanıklılık için kalınlaştırılmış paslanmaz çelik kullanır.

- Giriş/çıkış tasarımı, ana çalışma alanının dışında güvenli çalışmayı sağlar.

- Sistem, kısa döngü kesintilerinden kaçınarak kesintisiz boşaltma ile sürekli çalışmayı sağlar.

- Paralel bağlantılı altı grup işleme kapasitesini artırır; daha sonraki bir seri grubu, etkili kum çıkarma ve kapsamlı çamur ayrımı için çift aşamalı filtrelemeyi gerçekleştirir.

- Ev 304 paslanmaz çelikten yapılmıştır, kolay temizleme ve hijyen standartlarını karşılamaktadır.

4Makine tipi:

| Türü | Kapasite | Malzeme |

| DS2 | 10 t/saat taze manioka | SS304 veya naylon |

| DS4 | 15 ton/saat taze manioka | SS304 veya naylon |

| DS4+1 | 20 t/saat taze manioka | SS304 veya naylon |

| Çıktı başına özelleştirilmiş | SS304 veya naylon | |

5. teslimat fotoğrafı:

![]()